Jewelry Laser Welding – Prongs Repaired

What are jewelry prongs, what Is a prong setting, and how do we repair them? The prong setting or claw setting, is the main area in a ring that is required to hold the gemstone(s) in place. It usually has four to six metal prongs that extend up from the ring’s basket and extend over the gemstone to hold it. This effectively secures the diamond or gem in place and allows light to enter the stone.

The vast majority of prong settings are designed to last many years. White gold and platinum prongs are the most durable and can last 15-20 years, whereas yellow gold prongs and rose gold prongs have a shorter lifespan. Generally, the larger the prong, the longer it will last. So small prongs on accent Diamonds are more prone to wear and will need more attention than larger structural prongs, though the prongs that are most exposed to wear can also wear fastest.

What happens when the prongs are worn or you have a broken prong? There are two ways to repair prongs: we can either replace them with a new head setting, or add metal and retouch the existing prongs to stay in place. One of our repair experts can evaluate the ring and advise you based on what we think would be best in your particular case. Federal Way Custom Jewelers is able to undertake more complex and delicate repairs, since we have invested in a Laser Soldering Machine which focuses the heat to a more pin-point area of the prong, allowing us to work precisely while protecting the integrity of the stone(s).

The most frequent repairs we see are those pertaining to prongs in rings. Sometimes a client notices the ring is catching on clothing, which indicates that a prong has lost contact with the gem it is holding and has become a “lifted prong.” Other times the client looks down and sees a prong has been totally worn or broken away. In ideal circumstances, prongs are thick and sturdy at their base but also sturdy and solid on top, in firm contact with the gem, such that the gem is securely held.

|

|

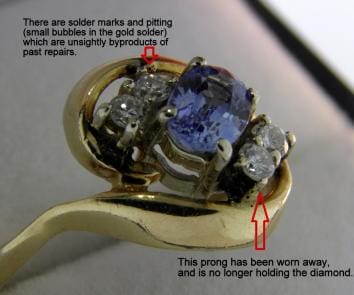

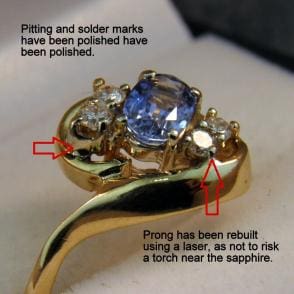

In the case of the above ring it was not immediately obvious that there was a problem at all. The worn prong was holding one of the smaller accent diamonds, and simply due to its small size was difficult to see with the naked eye. Furthermore the prong was worn down but had not quite disappeared all of the way. It was still a bad situation because one knock would displace the prong and cause the diamond to fall out.

A typical prong repair involves adding gold solder to the existing prong and using a torch to heat and bond the new metal. This poses a risk to the other stones around the prong in question, so in this case using a laser to re-tip the prong was in order. The laser focuses the heat needed to melt the metal in a much smaller area so that the repair is more precise, leading to less risk to the stones overall, and leads to a cleaner outcome.

As with any repair at FWCJ, while we were repairing the prong we took the opportunity to polish some of the flaws in the metalwork. Older repairs tend to show their age. In this case there were visible darkened solder marks, pitting (also called porosity) in the metal from badly applied solder, and some lumpy areas. Luckily it was nothing a little bit of expertise and elbow grease couldn’t fix. The end result is gorgeous!

If you have some jewelry where the stone in the ring has worked loose or is not fitting correctly, why not contact us so we can advise on the best way to get your ring expertly repaired and back onto your finger again. If you are worried about your prongs, come see our GIA-trained jewelry experts who can guide you through your best options and work with our master goldsmiths to orchestrate a fix.